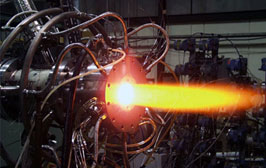

Testing gas turbine combustors and other equipment under high pressure conditions

Research mainly of combustion performance, exhaust characteristics, and cooling performance

This facility was introduced to test gas turbine combustors and their element technologies under high pressure conditions to conduct research on mainly of combustion performance, exhaust characteristics, and cooling performance. There are three types of systems for testing maximum pressure, i.e. the 5 MPa high pressure system (2 systems) and 1 MPa medium-pressure system. At present, this facility continues to be used in the development of high-performance industrial gas turbine combustors and jet engine combustors. In addition to an array of temperatures and pressure, exhaust gas components (nitrogen oxides, etc.) can also be measured. Tests can be carried out for comprehensive performance, including the environmental performance of combustors.

| Department | Aviation Technology Directorate |

|---|---|

| Air supply units | Two 720 kW units, one 1,900 kW unit; Two-stage pressure boost, owing to a motor driven multi-stage centrifugal compressor |

| Feed unit | Inlet air pressure: 1 to 5 MPa Inlet air temperature: 400 to 1,000 K (*730 K) Inlet airflow volume: 4 kg/s (maximum) |

| Year of completion | FY 2000 (*FY 1982) |

| Exhaust time/time for return to atmospheric pressure | approx. 24 hours/approx. 30 hours |

| Fees | Rig A: 146,767 yen/hour (Current as of April 1, 2024) Rig B: 190,250 yen/hour (Current as of April 1, 2024) *The usage fee above includes the general management fee. *The usage fee above does not include technical fees and consumption tax. These fees will be charged separately. *The usage fee above does not include required support fees, such as for operations. These fees will be charged separately depending mainly on the test details. *The usage fee is calculated each fiscal year. In addition, prices may be revised without notice midway through the fiscal year. Inquire using the form below for details. |