YUKI Precision

SPACECRAFT MACHINING

History

Yuki Precision has over a half-century of experience in precision machining. With the integration of experience and innovation, we will solve any challenge for machine part production. We think of ourselves as a R&D machine shop, implementing a research and development approach for your production needs.

Business

We offer expertise in complex and precise machining of stainless steels, titanium and other difficult-to-machine materials, providing precision components for various applications including the aerospace and medical industry.

Products/Services

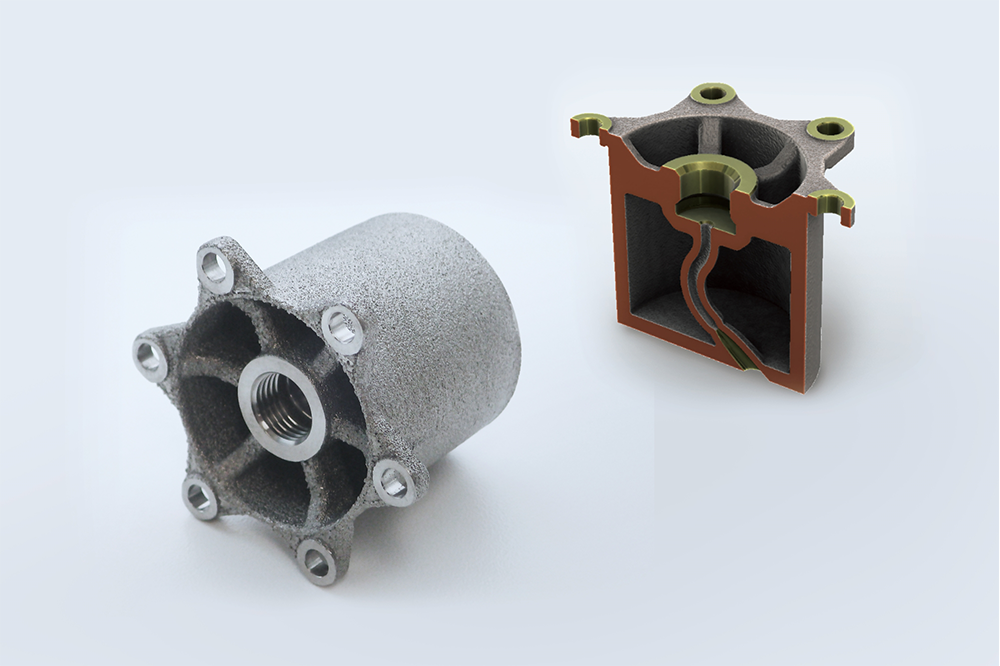

THRUSTER UNIT FOR MICROSATELLITE

Low toxic monopropellant thruster in a convenient safe compact package suitable for use in micro satellites. In development with research subsidized

by NEDO.

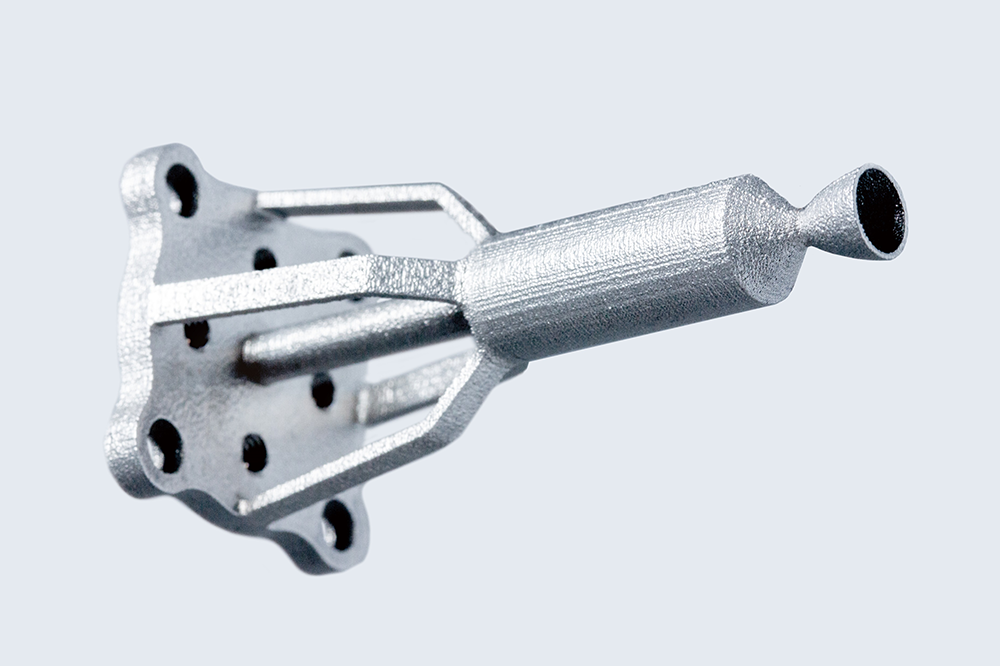

TITANIUM NOZZLE

RCS nozzle for use in experimental re-entry vehicle. Flow path and structure are 3D printed after which nozzle, valve connections, and locating elements were precision machined.

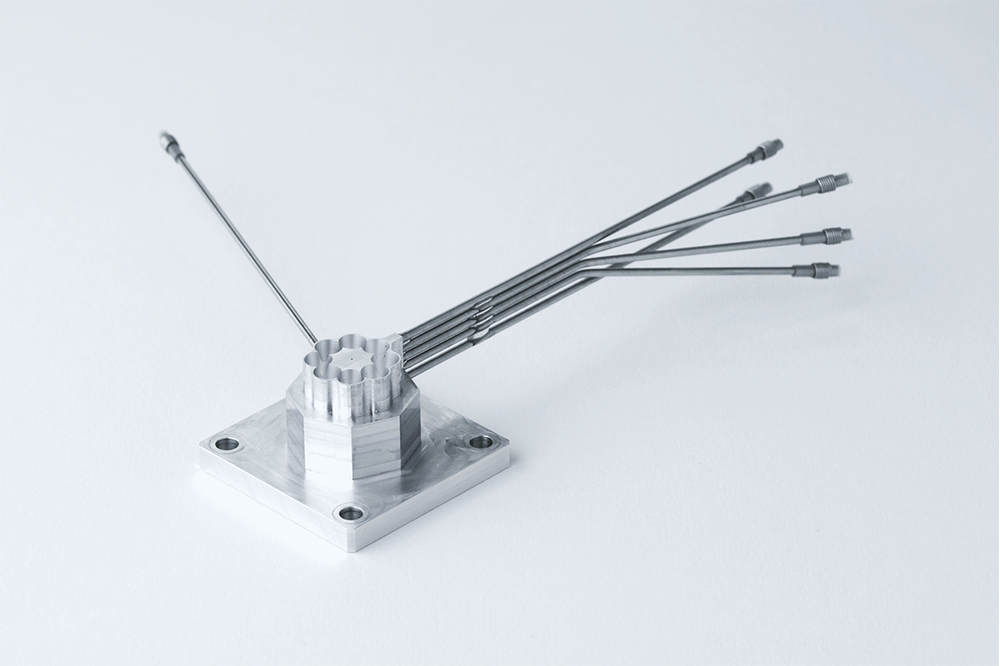

CLUSTER NOZZLE

Scale model nozzle to test new propulsion designs at JAXA. Made from aluminum alloy, pressure sensing orifices are 0.3mm in diameter. Part of a series of propulsion test bench equipment.

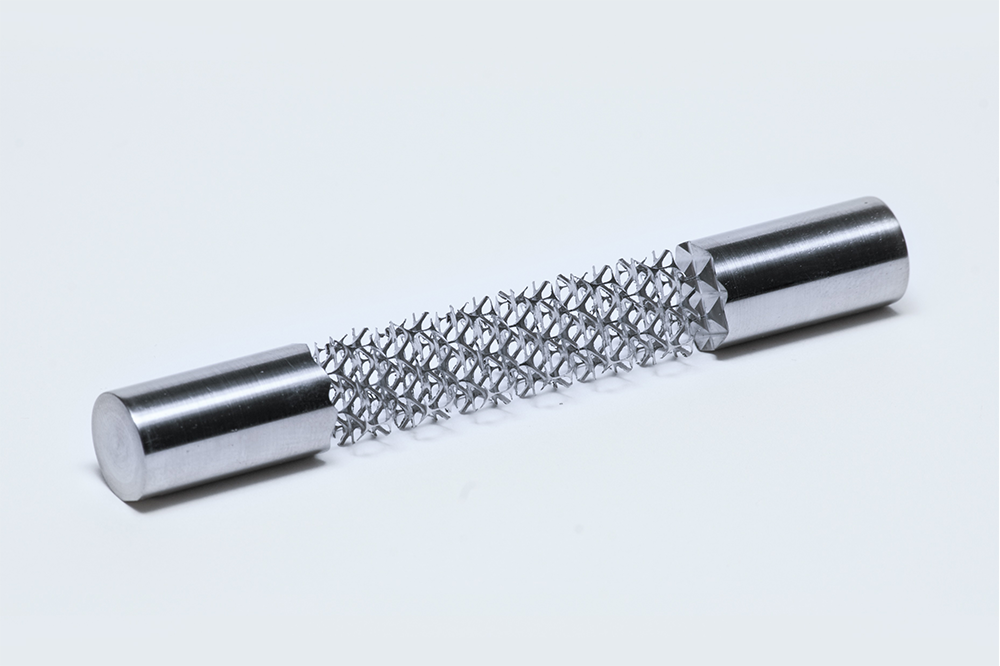

INCONEL MESH

Demonstration piece to show our capability to machine special alloys usually categorized as difficult to machine. Made by cutting a honeycomb structure from perpendicular axes.

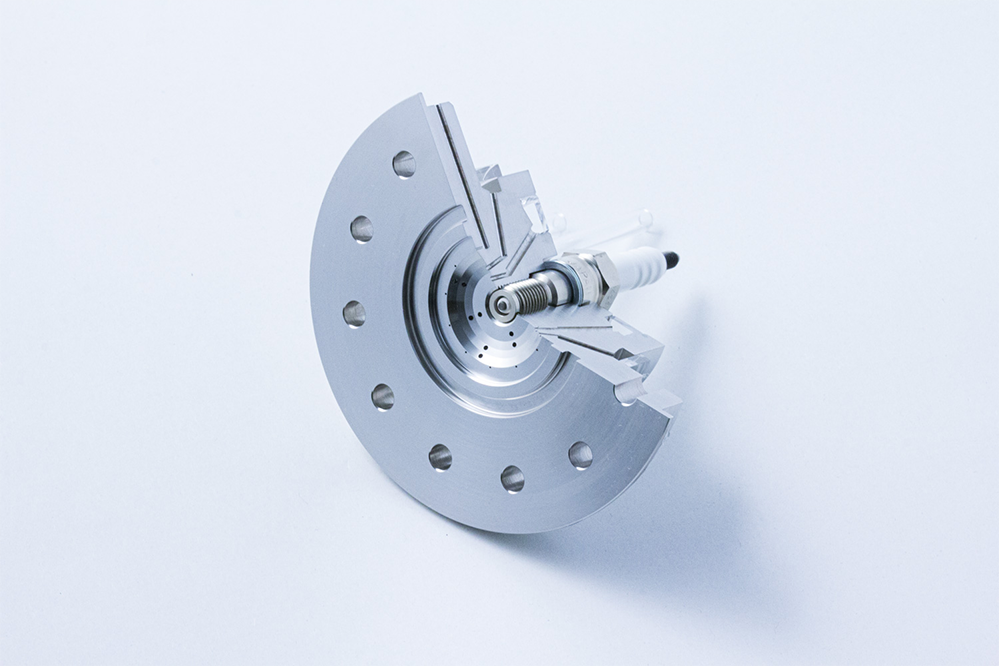

ROCKET INJECTOR

Liquid-propelled rocket injector demonstration piece. The injector piece is made from heat resistant nickel alloy. Orifices are small as 0.4mm diameter.

R/C WHEEL

Machined for one-off R/C model car. Accurate reproduction of curves and features of the original design.

Main Clients

Axelspace Corporation, Astroscale Pte. Ltd, Japan Aerospace Exploration Agency