Everything from the designing of patterns for printed circuit boards to the production of printed circuit boards is carried out on an integrated basis under one roof.

Renowned as a castle town on the Shonai Plains, Tsuruoka City, Yamagata Prefecture, is home to many companies with ties to the automotive and communications sectors. OKI Circuit Technology’s head office and plant are located in an industrial park not far from JR East Tsuruoka Station and have been manufacturing printed circuit boards since 1980.

Printed circuit boards are electronic parts made by forming circuits with conductive metal foil on boards as the base. Electronic circuits are formed by soldering electronic parts—integrated circuit chips, resistors, condensers, and transformers—onto printed circuit boards. Solder is sometimes coated to achieve a better flow onto circuit parts while gold plating is sometimes applied for improved electric conductivity.

Before printed circuit boards were introduced to Japan in the 1930s, electronic circuits were formed by connecting individual parts to one another with electric wire. By using printed circuit boards, complex circuits can be more easily manufactured and completed circuits are miniaturized. When first introduced, they consisted merely of a single-layer substrate formed by applying a copper circuit pattern to the surface of the base. Later, both sides came to be used. This was followed up by the insertion of insulating material in a way that allowed multiple layers of fine circuit patterns to be stacked atop one another. The printed circuit boards manufactured by OKI Circuit Technology currently consist of up to 50 of these layers with a single wire miniaturized to 50 micrometers in width. The base consists of rigid boards, as well as boards made from flexible, supple materials.

Once wiring is miniaturized to this extent, an extensive accumulation of expertise is required in terms of design and production. For example, parts through which high-frequency signals pass require that the signal transmission speed be controlled by using materials with a low dielectric constant. This company endeavors, as a full-time manufacturer of printed circuit boards, to accumulate such knowledge by carrying out everything from the design of patterns to the production of printed circuit boards on an integrated basis under one roof.

While up to 200 different types of substrates are manufactured each day, approximately 30 on average of any given type are produced. The plant is a picture of extreme contrast between the large number of types and the small volume of each type that are manufactured. For this reason, printed circuit boards for space applications are inserted into gaps for the production of printed circuit boards for industrial purposes and are manufactured according to special procedures for space. Reliability is heavily emphasized for printed circuit boards for space applications.

The company has obtained certification for printed circuit boards from JAXA for up to 10 layers. In the future, the company expects to have the scope of certification expanded.

Situated in Tsuruoka City, Yamagata Prefecture, the head office and plant of OKI Circuit Technology has produced printed circuit boards since 1980, back when it was known as Tanaka Kikinzokup>

Patterns for printed circuit boards are developed and designed with CAD (computer-aided design) software according to client needs.

Substrate patterns are subject to a printing process that occurs in a class 10,000 clean room, where light of a non-photosensitive wavelength region is used.

Substrates for which parts other than a printed pattern are removed through etching are inspected (left) and, if required, fixed (right).)

Substrates on which patterns have been formed are layered in a press machine. The company manufactures high-performance printed circuit boards with up to 44 layers.

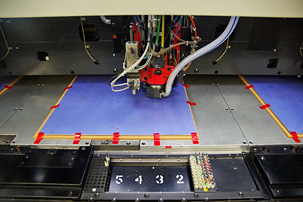

In the perforation process, lead insertion holes or mounting holes for electronic parts are created with a drilling processing machine.

Drills for printed circuit boards whose production quantity is relatively high are supplied by a robot (left).

In contrast, this process relies on the involvement of human beings for printed circuit boards characterized by the production of many kinds in small quantities (right).

An X-ray inspection device is used to determine whether holes have been drilled in the correct positions on each substrate and for other checks.(left)

Router processing is carried out to fabricate the outline, openings, and other elements of each substrate.(right)

Wiring testers are used to inspect the continuity and open circuitry of manufactured printed circuit boards. The company employs an array of 18 units.

Impedance testing is shown in these photographs. Two types of testing machines (left and middle) and manual testing (right) are properly employed according to the volume of production.

The external appearance of each printed circuit is visually inspected. Such a strict system of inspections underpins the high level of quality of the printed circuit boards manufactured by this company.(Left).

Thermal shock testing equipment is used to carry out approximately 1,000 repeated cycles of thermal shock testing on printed circuit boards for space applications.(Right)

OKI CIRCUIT TECHNOLOGY Co., Ltd.

INTERVIEW

インタビュー

Printed circuit boards for space applicationsare subject to testing that is ten times as strictas testing for conventional circuit boards.

OKI CIRCUIT TECHNOLOGY

Executive officer,general manager of production department

kazuyuki Saito