Absolute precision through cleanliness management and the pursuit of zero tolerance

High reliability is the absolute requisite for equipment installed onboard satellites, as no one on the ground can easily go into space to repair it.

JAXA staff visited the Mitsubishi Precision’s clean room where bearings, the key parts of an aerospace-quality reaction wheel, are assembled. At Mitsubishi Precision, bearings purchased from a manufacturer are first disassembled and cleaned, and then assembled while confirming their properties to enhance the reliability of the component.

The long-standing reliability of such bearings over one or two decades is due to two major factors. One is the work to remove dirt, known as contamination. The smallest balls (about 1 mm in diameter) in ball bearings used for satellites cannot function properly when micron-sized particles of dirt adhere to them.

The other key factor is the amount of lubricant applied to the bearings. Excessive lubricant increases the rolling resistance of the bearings, while insufficient lubricant results in friction that causes the bearings to deteriorate.

Accordingly, no dirt in the well-controlled environment and application of the precise amount of oil are critical for ensuring the reliability of the parts.

Clean Room Class 100. Employees focusing on their detailed work.

The precise amount of oil at the microliter level is manually injected into a ball of a ball bearing by using an ultrafine syringe-like instrument (micro syringe) as viewed through a telescope.

The bearing being assembled is examined to check its placement parallel to the surface, on which a gyroscope is installed, with its axis vertical. The strict standard only allows micron-level tolerance.

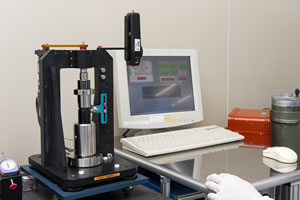

Once assembly is completed, the bearing is examined to confirm that there is no assembly failure and no dirt inside, and that the appropriate amount of lubricant is applied by measuring the bearing’s resistance while rotated.

Units for checking the condition of assembled bearings by a running-in operation with a given number of rotations for a certain period of time. Among them is a unit for rotating a bearing in the atmosphere and one for rotating a bearing under a vacuum.

The station where the cleaning solution for cleaning parts is prepared. The cleaning solution after being filtered and a specific glass implement made of 100% quartz that generates no dirt are used here.

A single body of a 6-kg rotor actually used for a reaction wheel. The mirror finish of its surface prevents dirt from being generated and adhering to the bearing. The hole on its side is a screw hole used when fine tuning the rotor’s balance. The bearing supporting the top and bottom of the shaft in the center changes a satellite’s attitude by changing the rotor’s rotational speed.

Parts used for the satellite attitude control unit. Tiny bearings are built in the parts.

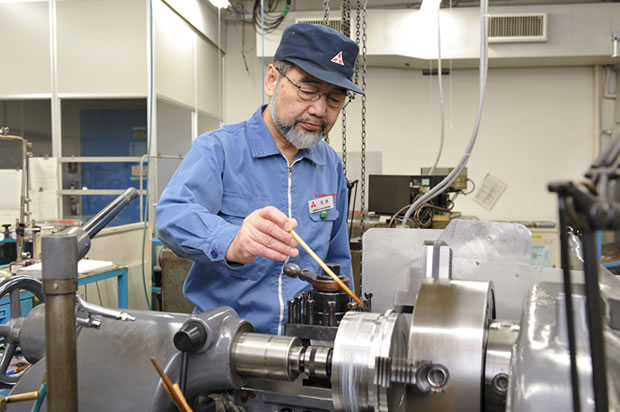

Mr. Masahiro Kawahara, honored as a Contemporary Master Craftsman by Japan’s Ministry of Health, Labor, and Welfare, turning the parts of the reaction wheel. Excellent craftsmanship by employees as developed through years of experience, including the post-process measurement setting in light of the thermal expansion of materials and the installation method in light of deformation, bolsters the company’s aerospace quality.

Mitsubishi Precision Co., Ltd.

INTERVIEW

インタビュー

Mitsubishi Precision, Japan’s pioneering space-related equipment company, has been engaged in space development for over a half century.

The company develops 100% domestically produced reaction wheels!!

Mr. Satoshi Yasui, Director and Head of the Kamakura Plant *

(* Mr. Yasui is currently the Corporate Adviser (December 6, 2017).)