The world's only CdTe radiation detector manufacturer performs the processes from material refining to mounting.

The Astro-H X-ray astronomy satellite is scheduled for launch in 2015 and will carry advanced observation instruments—the company involved in the manufacture of one of the instruments onboard is located in Uruma City, Okinawa. Acrorad Co., Ltd., develops and manufactures cadmium telluride (CdTe) semiconductor-based radiation detectors. This company is characterized by the consistent process from refining of Cd and Te to mounting of CdTe devices with Si circuits and is the only company in the world making a profit among the manufacturers that offer such detectors.

CdTe, which is used for detectors, has the advantage of being able to achieve higher radiation detection efficiency and operate at room temperatures compared to silicon (Si) and germanium (Ge), which have been traditionally used. (For example, for Ge, a cooling device that uses liquid nitrogen at – 196ºC is required.) In addition, CdTe also features high density to achieve sufficient detection accuracy even though the device is thin. Approximately one millimeter-thick CdTe devices can detect X-rays.

The strong point of Acrorad is that it established the technology for manufacturing highly pure, highly resistive, and large CdTe crystals. This technology is supported by the company’s extensive expertise accumulated from over twenty years of research. Acrorad quality is supported by expert knowledge in the conditions that need to be met for sufficient crystal growth and the methods of forming electrodes, which cannot be obtained from patent information and articles.

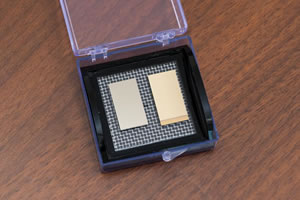

Left: CdTe device, Right: Silicon circuit

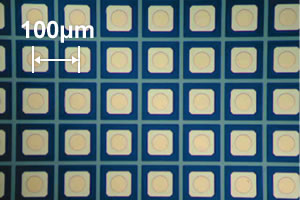

Picture elements on a CdTe device surface

Thirty thousand picture elements are arranged at 100 micrometer-intervals on both a CdTe device and a silicon circuit, which are as small as a fingernail. The CdTe device and silicon circuit are overlaid on each other in a way that the picture elements on both parts overlap to create a two-layer hybrid device.

The Acrorad headquarters and plant in Uruma City, Okinawa. According to Acrorad, it had been in the red for the first eleven years since its establishment and experienced a cumulative deficit of up to 1.3 billion yen. As a result of a subsidy from the government and Okinawa Prefecture, as well as obtaining a loan from investors, the company became profitable in its twelfth year. Current plans are to expand the plant for mass production.

Zone refining system

Crystal growing system (THM method)

The purity of cadmium (Cd) and tellurium (Te) is increased from 99.99 % to as high as 99.9999% by using a zone refining system. After that, a crystal growing system (THM method) is used to grow a single CdTe crystal. It takes more than one month until the crystal grows to the size required for commercialization.。

The clean room houses the machines for cutting column-shaped CdTe material and for polishing the wafers (strips).

A wafer before the polishing process (upper left) and a wafer after the polishing process (center) A polished wafer is like a mirror.

A CdTe wafer with formed electrodes is cut (singulation process).

A single CdTe crystal grown into a cylindrical shape is cut into 0.5–3 millimeter-thick wafers according to the intended use, and they are mirror-polished using a system to form electrodes. In the final stage, the quality and performance of detectors are examined carefully by human eyes to check for any cracked picture elements.

Acrorad Co., Ltd.

INTERVIEW

インタビュー

Participation in space developmentis an investment in the future.

ACRORAD

CEO and PresidentRyoichi Ohno