Armature plant fosters a culture of reliability and high skill.

Sinfonia Technology uses its technology for building motors, generators and applies those core armature technologies to aerospace, automatic ticket vending machines at stations, transport system, clutches and brakes, high-speed printers, wind power systems and to developing other various of industrial machinery.

The company’s predecessor was created in 1917 in Mie Prefecture and was built inside the Toba Shipyard as an electrical machinery works. The shipyard later came under the umbrella of the Suzuki Shoten group and became Toba Works, operated by Kobe Steel. The shipyard then split off from Kobe Steel in 1949 and established an independent company called Shinko Electric, a name it kept until 2009.

The company’s current name, Sinfonia Technology, was chosen based on an ideal of creating harmony between the diverse products and technology it handles to conduct one unified technical symphony.

Around 10 billion yen of the company’s total sales of roughly 70 billion yen are in the aerospace sector. Accounting for a seventh of sales, the sector has been a major pillar of growth for the company’s business. Among the equipment that Sinfonia Technology produces for use in space are attitude control servo-actuators for rockets and ventilation fans for Kounotori 2, the Space Station cargo ship.

Sinfonia Technology’s Ise Plant in Ise, Mie Prefecture works on aerospace equipment. Because of the high reliability this sector demands of the products it uses, the Ise Plant puts a heavy emphasis on its technicians’ skill, creating a culture that focuses on quality, reliability and worker skill even more than the rest of the company. Aerospace is also a field that demands security for its technology, so all of Sinfonia Technology’s personnel involved in the field now are full-time, permanent employees.

Sinfonia Technology makes all its aerospace equipment here at its Ise Plant, which works on machinery including small wind turbine generating systems, industrial vehicles, automatic ticket vending machines, electromagnetic clutches and brakes, and printers.

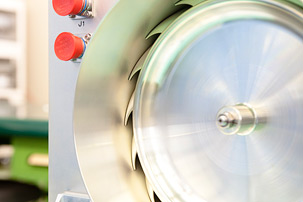

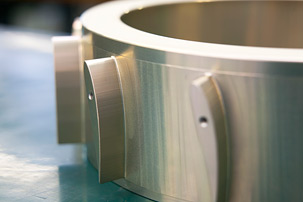

This is a ventilation fan for Kounotori, the Space Station cargo ship that carries supplies to the International Space Station (ISS). It is used in the ship’s pressurized logistics carrier.

Because the fan is used inside the station where astronauts work, it has to run quietly. Therefore, Sinfonia Technology subjected the rotor vanes to a succession of tests to get their shape just right.

This is a fan testing device. It verifies the airflow volume and the static pressure in order to ascertain the fan’s performance.

The objects on the cylindrical exterior are the stator vanes. Just like the rotor vanes, the stator vanes are tested to establish their optimal shape.

Highly skilled engineers, such as those pictured soldering circuits , work on aerospace equipment manually. Visual inspections are essential for every job in order to ensure reliability.

Sinfonia Technology assesses worker abilities and only allows the highly-skilled to work at the Ise Plant. The white piece of equipment in front of the engineer pictured is an aspirator, which absorbs gas and dust during soldering.

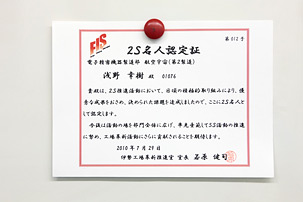

Commendations are displayed on a whiteboard inside the plant. Here, one employee has been recognized as the best in two of the 5S which is the name of a workplace organization method that uses a list of five Japanese words: seiri, seiton, seiso, seiketsu, and shitsuke.

SINFONIA TECHNOLOGY

INTERVIEW

インタビュー

Just doing design is not good enough.

The technical skill and production technologies

are also important.

SINFONIA TECHNOLOGY

Electrical Precision Machinery Division Vice Director, Board Member

Shinichi Kimoto