Building and testing astronautic parts ona factory site which still remain pre-war buildings

NIPPI Corporation (NIPPI) started out building flying boats and training aircraft for the Japanese Navy in 1934. At the close of World War II , the company was testing the “Shusui” rocket interceptor. After the war, NIPPI built a mock-up of the Japanese-made YS-11 airliner, pylons and launchers for the F-15 fighter flown by the Self-Defense Forces (SDF) and more.

Recently, NIPPI has enthusiastically jumped into the business of manufacturing parts for non-Japanese airliners, including: inspar ribs and front landing gear doors for the Boeing 777; external flaps, main landing gear doors and fuselage frames for the Boeing 747; and the tail assembly end for the Airbus A380. NIPPI has particularly focused on carbon-fiber-reinforced plastic (CFRP) molding. During prepreg lamination, NIPPI workers manually layer the pieces and check their condition. It’s a job that demands expert skills.

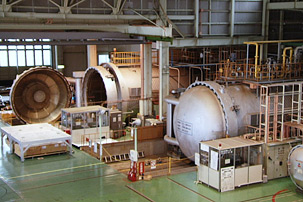

NIPPI’s Aerospace Division in Yokohama is the company’s production base for aircraft and space equipment. Some of NIPPI’s pre-World War II structures–the administrative building and factory with its triangular roof–still remain on the premises. Space equipment is built and tested in a modern clean room in one section of the site.

NIPPI’s Aerospace Division in Yokohama is the company’s production base for aircraft and space equipment.

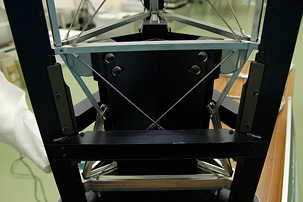

This is the coilable mast used by the BepiColombo Mercury probe. It folds up to a compact size for launch. In orbit, the end, equipped with magnetic sensors, extends out to five meters to prevent magnetic interference on the probe’s main section.

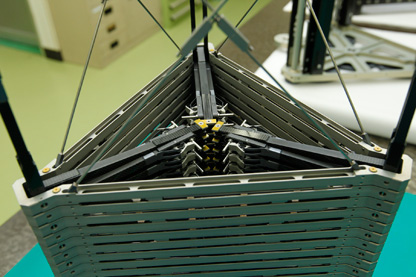

This demonstration coilable mast looks flexible, but the truss structure makes it surprisingly rigid when extended.

This highly rigid mast used by the ASTRO-H X-ray observation satellite is normally stored compactly, but can extend out to six meters. As the name implies, it is much harder than a coilable mast. X-ray observation equipment is affixed to the end of this highly rigid mast to extend the telescope’s focal length and make very accurate observations.

This jig, used to build the highly rigid mast, was made for the sole purpose of building that one piece of equipment, which can only be used for the ASTRO-H.

The photo shows a highly rigid mast used for demonstration. The actual mast will extend to deploy solar panels, antennas and the like

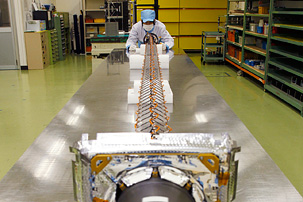

Here, a worker is assembling the wire antennas for the BepiColombo probe. The gold wire is the antenna, the end of which will connect to the ball shown in the photo on the right, then use centrifugal force to extend the antenna out to a length of 15 meters. The BepiColombo will have two such antennas.

This is the prototype of the device used by the Hayabusa asteroid probe to detach the re-entry capsule, which separated by employing a spiral-shaped “screw.” Giving the capsule spin allowed Hayabusa to release it safely.

The Aerospace Division’s aircraft production line features a row of autoclaves for CFRP molding.

The aging main building, constructed in 1938, is unfortunately scheduled for demolition in 2012.

NIPPI CORPORATION

INTERVIEW

インタビュー

We're focusing on parts

with high added value

that no one else can make.

NIPPI CORPORATION

Aerospace Division Director Kohei Aizawa(Position is current as of the time this interview was conducted.)