A Company that also harnesses resarch facilities

operated the Graduate School for the Creation

of New Photonics Intdustries.

The TAK System Initiative is an optical technology venture company developing prototype optical measurement devices and measuring light on a contract basis. Established in October 2007 and with only three employees, this enterprise is involved in a wide range of light-related products, including visible light and ultraviolet ray spectroscopes, laser scanning microscopes, photon image measurement devices, distortion image measurement devices, light scattering transmission field measuring devices, integrating circuits, and laser equipment. Radiation-measuring instruments that can be coupled with in-vehicle GPS units have also been developed in response to the nuclear power plant accident in Fukushima.

Yoshihiro Takiguchi, representative director of this enterprise, is also a university professor at the Graduate School for the Creation of New Photonics Industries. This university aims to accept people as students who are willing to start businesses in new photonic industries and to provide support. That the research facilities of this university can be used in addition to the Azukimochi Development Center operated by this enterprise in Hamamatsu City, Shizuoka Prefecture, is a competitive advantage enjoyed by this R&D-based enterprise.

In the space-related field, this enterprise has been developing artificial opal using the ISS (International Space Station) since 2008. When this material is perfected, it is expected to have a wide range of applications as an optical element for use in optical communication devices and laser elements.

This enterprise is currently taking on the challenge of developing a telescope that can be mounted onto small satellites. The aim is to obtain expanded images with a concave mirror measuring 20 centimeters in diameter, take video clips with a camera, and send such data in real time to the surface of the earth.

A simple darkroom somewhere in the Azukimochi Development Center. A simple prototype can be developed here.

Next to the darkroom is an environment furnished with a lathe, miller, and band saw to enable devices needed for experiments to be made by hand.

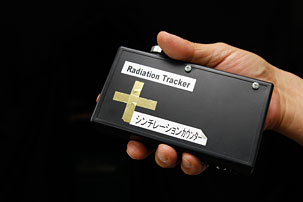

Upon finding out about the accident at the Fukushima No. 1 Power Plant in the wake of the Great East Japan Earthquake, representative director Takiguchi promptly developed an inexpensive radiation dosage meter for taking measurements in real time. Amounts of radiation were measured in Fukushima. Pictured here is a radiation dosage meter that was actually brought to Fukushima at the time.

Representative director Takiguchi, who additionally works as a researcher with Hamamatsu Photonics, is also working to develop artificial opal on the ISS (International Space Station). This material is expected to be applicable as an optical element for use in household optical communication devices and lasers.

The TAK System is involved in the production of many spectrum measurement devices. These devices take many forms, depending on the wavelength of the light being measured and the purpose of use.

An integrating sphere is a device designed to reflect the light of a light source set up inside the sphere or light entering from outside the sphere along multiple paths and to measure the resulting luminous flux.

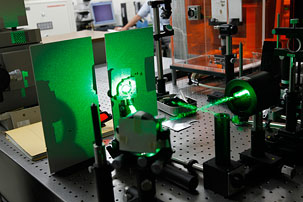

Also located in Hamamatsu City, the experimental laboratory of the Graduate School for the Creation of New Photonics Industries serves as the fundamental research laboratory for the TAK System. In this laboratory, a YAG (yttrium aluminum garnet) laser beam is directed at a metal surface. Material analysis is conducted by taking spectroscopic measurements of the resulting plasma.

A laser interferometer for taking measurements of telescope mirrors and other such objects. Measurements with nanometer precision can be taken. Shown on the right side of this illustration is a vacuum chamber measuring 30 centimeters in diameter. It has been designed to create a pseudo-version of outer space for inspecting the environmental resistance of mirrors in outer space with a laser interferometer.

TAK SYSTEM INITIATIVE

INTERVIEW

インタビュー

We have taken on the challenge of developing a small space telescope

by leveraging the competitive advantages of local companies

based right here in Hamamatsu.

TAK SYSTEM INITIATIVE

Representative Director

Yoshihiro Takiguchi