Kyocera's mother plant,where a wide variety of products are handled by the company

Situated in the city of Higashiomi, Shiga Prefecture, the Shiga Gamo plant is one of the sites operated by Kyocera’s Corporate Fine Ceramics Group. Having begun operations in 1963, this plant is the first mass-production plant owned and operated by Kyocera. The integrated production of items from scratch (raw materials) is a salient feature of this plant. All processes—from the preparation, molding, sintering, and processing of raw materials and the joining of the results with metals by way of metallization to the finishing of products—are carried out at this plant.

An exceedingly wide variety of items are manufactured at this plant, including machine parts for pumps and valves, insulating parts for use in the relay boxes found in electric cars, cases and other parts for electronic devices, electronic parts as typified by inductors for mobile phones, and parts for semiconductor manufacturing equipment and ultra-high vacuum equipment, as well as artificial joints and other medical materials coming under the charge of other group companies. Parts manufactured at the Shiga Gamo plant are even used at Spring 8, a large synchrotron radiation facility in Harima Science Garden City in Hyogo Prefecture, and LHC, a large particle accelerator operated by the European Organization for Nuclear Research on the border between Switzerland and France. With technology developed here having been transferred to other plants, this plant is known as Kyocera’s mother plant.

The manufacturing of ceramic parts begins with the preparation of raw materials still in their powdery state. Prepared materials (known as secondary materials) are pressed together into the intended product form using a precision die. Where necessary, a pre-sintered half-finished item that has been pressed together will be subject to cutting. Ceramics shrink about half their size when sintered. A considerable amount of expertise is accumulated by the time one can decide on the dimensions of a die in anticipation of the final measurements. For a precision part, post-sintered cutting is carried out to achieve the required degree of precision.

For metallization, a metal paste known as metalizing ink is applied to the ceramic surface. Silk-screen printing is used where something is being mass-produced, but this ink is sometimes applied with a brush by a seasoned worker where small batches or single items are being produced. In such a case, the quality finish being sought will vary depending on the selection of the brush being used and the skill level wielded for the task.

Raw materials consisting of aluminum oxide and zirconia are crushed and mixed with a ball mill to create a slurry with particles of a given size.

Slurry is sprayed and instantly dried with hot air to create a fine powder.

There are a variety of methods by which materials are molded according to use. What is shown here is a Isostatic Press. Isostatic molding is filled with ceramic powder before water pressure is applied to mold the material (left). Pressed material is then cut and processed into the prescribed form (right).

Die Pressing machine is shown here. Powder material is filled in the mold and formed by applying pressure with the upper and lower punches.

With an extruder, material with plasticity is packed into a mold and high pressure is applied. It is thereby extruded which it is shaped accordingly.

The sintering process. Materials are sintered at high temperatures and required condition.

With a hot press, the powdery form of raw materials is packed into a mold. The press is heated while pressure is applied from above and below. A high-density sintered compact is obtained.

Hot isostatic pressing is a method of sintering a molded item that is exposed to high temperatures and high-pressure gas. Since uniform pressure is applied, a high-density sintered compact can be formed.

After sintering is completed, a diamond whetstone is used to polish the resulting item into a more high-precision product.

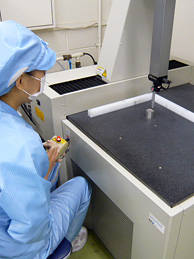

Space parts are subject to rigid inspections. From left to right: brazing inspection conducted visually, dimensional inspection using a Coordinate measuring machine, and insulation inspection using a tester.

KYOCERA

INTERVIEW

インタビュー

Destructive inspections were also required todevelop the battery terminal forthe Hayabusa spacecraft.

KYOCERA

Senior Manager, Ceramic Quality Assurance Department 1,

Fine Ceramics Quality Assurance Division, Corporate Fine Ceramics Group

Takuya Kitamura