Producing mainly space observation equipment--plus ultra-small satellites

Meisei Electric, established in 1938, is a maker of observational equipment and electronic systems. In its past, the company produced and mainly sold various equipment and circuitry to the Nippon Telegraph and Telephone Public Corporation (now known as NTT), but today the heart of Meisei Electric’s business is systems that combine measurement technology with data analysis, such as its earthquake information system and the Automated Meteorological Data Acquisition System (AMeDAS) for the Japan Meteorological Agency (JMA).

Space is another key line of business, which accounts for nearly 20% of the company’s sales. Meisei Electric has been in the field of Japanese space development since the dawn of the country’s space program, when Hideo Itokawa of the Institute of Industrial Science at the University of Tokyo developed his Baby Rocket (the successor to Pencil Rocket). Japan’s first satellite, OHSUMI , was equipped with a Meisei Electric-made directional coupler for its antennas. Ever since, most of Japan’s scientific satellites and Earth observation satellites have been equipped with Meisei Electric’s observational equipment. For example, eight of the fifteen observational devices on Kaguya, the Moon-orbiting satellite, were supplied by the company.

Recently, Meisei Electric has set out to develop and manufacture ultra-small satellites. The company plans to make itself stand out from other satellite makers by leveraging its experience with various observational equipment and the like.

Meisei Electric’s headquarters in Isesaki, Gunma Prefecture is where the company produces space equipment.

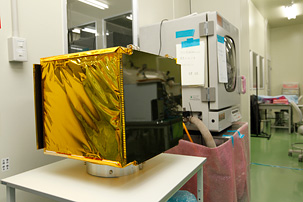

This life-size model of ultra-small satellite now under development is a cubic shape that is 50 centimeters along each dimension.

The WE WISH ultra-small satellite, shown here as a model, is a 10-cm square.

Meisei Electric installed a thermal vacuum chamber with a diameter of 1.2 meters to replicate the environment in space in order to develop the ultra-small satellite.

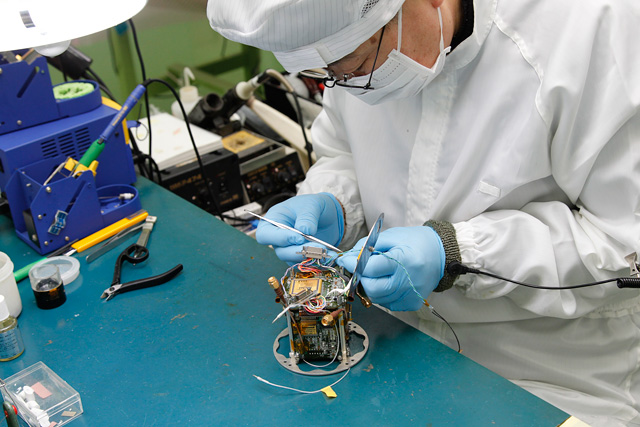

All space equipment is built in Class 50,000 to 100,000 clean rooms. The photo shows a worker replacing digital camera parts with those for use in space on Kibo, the Japanese Experiment Module (JEM).

Optical systems assembly and other such work that demands a particularly clean environment is performed in a Class 100 clean booth.

Products are meticulously inspected because they need to be highly reliable. In the left photo, a worker is checking dimensions with a 3D measurement device. On the right, a worker is checking an item’s electrical properties.

Here, a worker is assembling an observational device that will be loaded onto BepiColombo, the Mercury probe scheduled to launch in 2014.

Meisei Electric has set up this 10-ton vibration test machine to examine the effects caused by vibrations during a launch.

In contrast to Meisei Electric’s mostly hand-made space equipment, the manufacture of products other than space equipment is largely automated.

MEISEI ELECTRIC

INTERVIEW

インタビュー

Offering systems to the world,including applications

MEISEI ELECTRIC

Technical Development Division Director

Koji Shibata